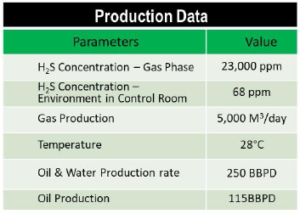

An oil and gas producer in Mexico was having difficulties maintaining low H2S levels in the in environment of the tank battery. The field produces 0.18 mmpcd of gas containing ratios > 20,000 ppm of H2S along with their oil production with readings of 500 ppm of H2S in the tank battery in the environment which created a hazard to the operators. The excessive H2S in the gas resulted in nonconformance with ASEA PEMEX regulations and posed a significant health and safety hazards for the employees working in that area. Quimicorp and FlowChem determined the that properties of MAXSCAV IHS-8000 with it’s fast reaction time would be capable of decreasing the H2S level to zero. In collaboration with the customer, scavenger injection point was moved to the production meter manifold.

PERFORMANCE EXCEEDS EXPECTATION

MAXSCAV® IHS-8000 decreased the H2S concentration in the

tank battery environment from 500 ppm to zero. This drastic

decrease allowed met the ASEA PEMEX regulation requirement

and eliminated health hazards for employees that may potentially

be exposed to the gas.

BOTTOM LINE: PERFORMANCE OBSERVATION:

The customer must to reduce the concentration of H2S in the gas MAXSCAV IHS-8000 reduced the concentration of H2S in the

to meet regulation requirements and decrease health and safety environment,ensuring effective treatment and helping the

hazards. customer meet regulatory requirements and decrease health hazards.

CASOS DE ÉXITO

Application of MaxScav™IHS-8000 in a

Mexican Oil Field Operation